Find Injection Molders in the US

Looking for an injection molder that manufactures in the US? InjectionMolders.net is a free resource for businesses looking to find manufacturers in the US that specialize in plastic injection molding.

Made in America

InjectionMolders.net supports “Made in America” initiatives by connecting businesses with local injection molders to manufacture their products. All molders listed on our site are required to have injection molding occur in the United States.

What is Injection Molding?

Injection molding is a manufacturing process for producing parts by injecting molten plastic into a mold. Injection molding can be used to create anything, from small components like buttons and bottle caps to large items like car bumpers and desk chairs. Injection molding is highly efficient, making it ideal for mid- to large-volume production.

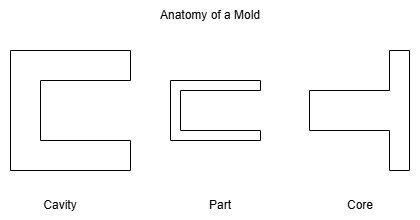

Plastic injection molding uses thermoplastic resin, which is fed into a heated barrel. Inside the barrel, a rotating screw melts the pellets into a molten state. This melted plastic is then injected at high pressure into a mold. The mold is typically made of steel or aluminum, and consists of two halves: the cavity (i.e. “A” side/female side) and the core (i.e. “B” side/male side). Once the plastic fills the cavity, it is rapidly cooled and solidified.

After cooling, the mold opens, and the solidified part is ejected. The cycle then repeats, often taking just seconds to complete. This makes injection molding extremely fast and cost-effective for producing large quantities of identical parts.

Injection molding is a great manufacturing process if you need high precision, excellent surface finish, and the ability to produce complex geometries. It also minimizes material waste, as many thermoplastics can be reintroduced to the process as regrind.

Despite its advantages, plastic injection molding does have limitations. The upfront costs for mold design and fabrication can be high, making it best suited for mass production where those costs are spread across a large number of parts. For small volume manufacturing, it can be more cost-effective to either machine the parts out of stock shapes or use additive manufacturing processes.